Types of dams are classified based on construction materials and site conditions, each serving different engineering and environmental needs. The main types—concrete, masonry, rock-fill, and earth dams—store water, control floods, support irrigation, and generate hydroelectric power. This post explores how engineers construct each type, their unique characteristics, and the conditions where they work best.

Types of Dams:

Dams fall into four broad groups depending on the construction materials:

- Concrete Dam

- Masonry Dam

- Rock-fill Dam

- Earth Dam

Concrete Dam:

Engineers subdivide concrete dams into three categories based on bearing strength and stability: gravity, arch, and buttress dams. Gravity dams feature straight or slightly curved axes and generally have triangular or trapezoidal cross-sections, with bed widths about two-thirds their heights.

Their downstream faces can be straight or curved. The thick concrete body provides the necessary weight to resist water thrust and uplift pressure. Builders prefer narrow valleys with sound rock for constructing concrete gravity dams, but they also strengthen the foundation to build them successfully on soft sedimentary strata.

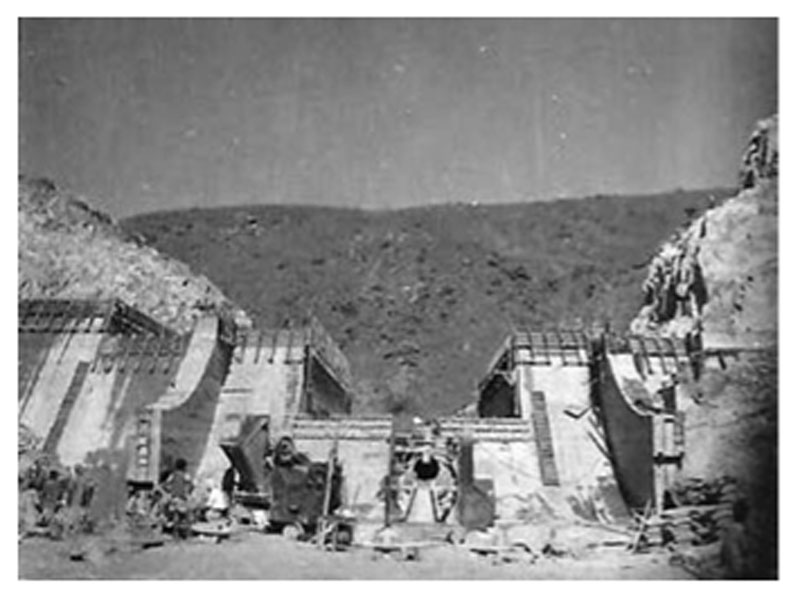

Fig. 1 Concrete gravity dam under construction across the river Umiam, Meghalaya

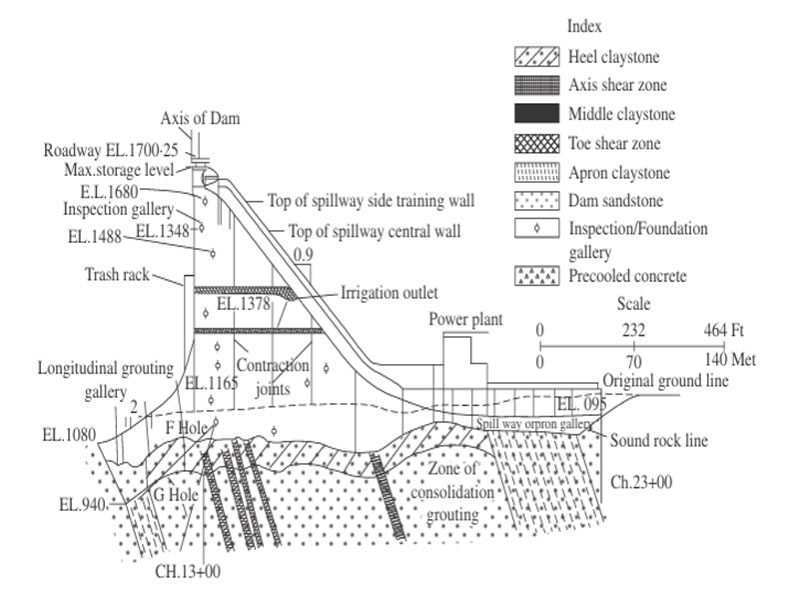

The 225.5 m-high Bhakra dam in Punjab ranks among the world’s tallest concrete gravity dams. It sits on shale–sandstone rocks of the Siwalik formation (Fig. 2). Figure 1 shows a concrete gravity dam under construction across the Umiam River in Meghalaya, where hard quartzite and arenaceous phyllite form the abutments and base.

Fig. 2 Different parts and foundation geology of Bhakra dam in Punjab (Geological Survey of India, Misc. Pub. No. 29, SL. PL. 2)

Arch dams curve in their design, hence their name. The 169 m-high Idukki dam in Kerala, built on massive granite gneiss in a canyon site, exemplifies a large arch gravity dam. Arch dams have a curvilinear plan with the convex side facing the headwater.

Vertically (in cross-section), these dams appear thin and curved. The arch action distributes part of the reservoir water’s thrust to the abutment rock. Designers shape the dam’s thickness and curvature to transfer more than half the load to the abutment.

Therefore, the abutment and foundation rocks must possess sufficient strength to bear the load. If over half the dam load rests on the foundation, the structure qualifies as an arched gravity dam. Builders usually construct arch dams in narrow valleys or canyons, where height exceeds axial length.

Buttress dams consist of massive, thin, or arched slabs supported by vertical walls or buttresses. The slabs with upstream slopes resist water thrust, while buttresses carry the load from headwater to the foundation. Steep beams or girders spaced between buttresses prevent bending.

Constructors use concrete or reinforced concrete for buttress dam components. Depending on shape, they may build flat slab types. Buttress dams require firm rock foundations where the buttresses sit. Since the interior is hollow, these dams use less concrete and cost less than other types.

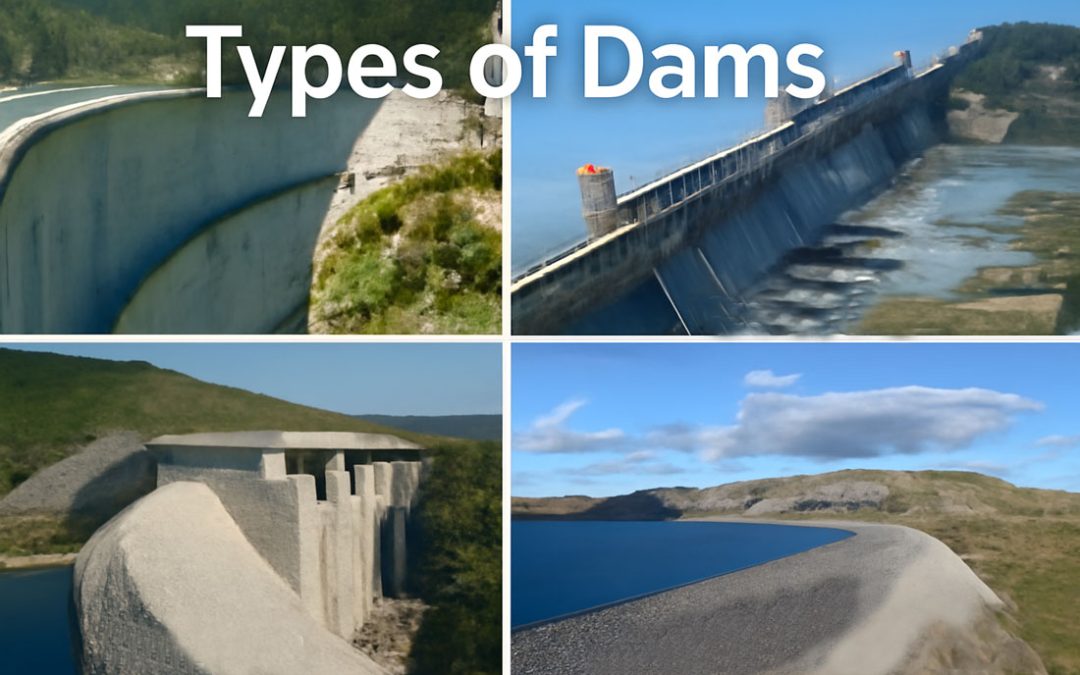

Masonry Dams:

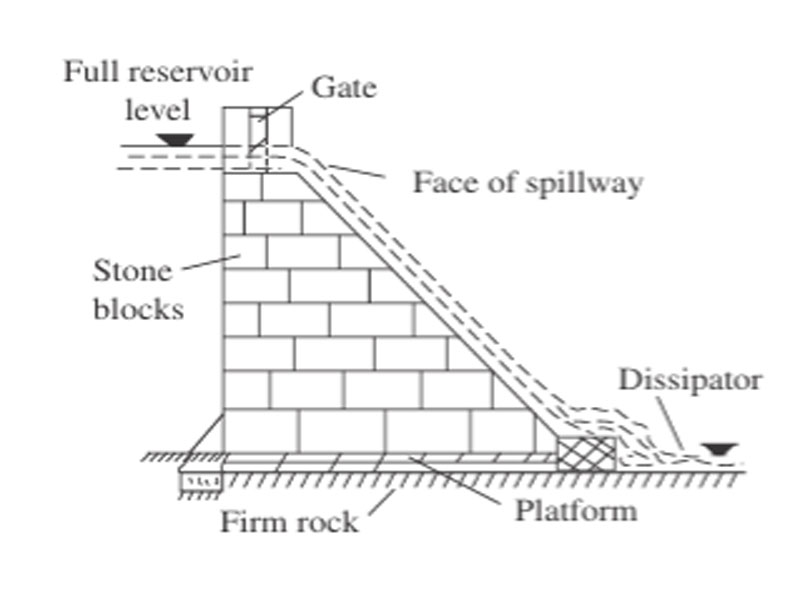

Masonry dams (Fig. 3) consist of large undressed rock blocks, including river boulders, bound by concrete. Builders select non-porous rocks to ensure the structure acts as a watertight barrier. The cemented joints between blocks must be sealed to prevent seepage.

Fig. 3 Masonry dam made of cut blocks of sound rock having gated spillway

India has many old stone masonry dams. The 139 m-high Srisailam dam in Andhra Pradesh serves as a good example of masonry construction.

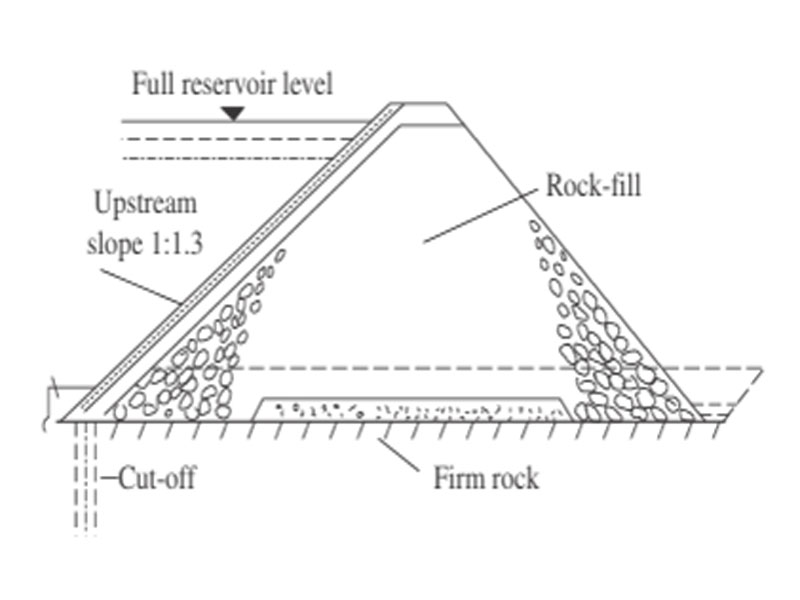

Rock-fill Dams:

Rock-fill dams consist of a mixture of ground spoils, river deposits (gravels, pebbles, boulders), and crushed rocks. They have trapezoidal cross-sections with side slopes steeper than 1:1. Depending on the impermeable membrane type, rock-fill dams fall into two categories:

- Dams with concrete walls on the upstream face, which create impermeable barriers against leakage (Fig.4).

- Dams with impervious earth or clay cores in the center, acting as impermeable membranes.

Fig. 4 Rock-fill dam with concreted upstream slope

Apart from the impermeable wall or core, the rest of a rock-fill dam remains permeable, even after compression. Over the past two decades, rock-fill dams have grown popular because large structures of this type cost less than concrete dams.

Fig. 5 Foundation preparation of the rock-fill dam of the Salal project of Jammu and Kashmir

Builders often use rock-fill dams in high seismic zones. The 116 m-high Salal dam in Jammu and Kashmir (Fig. 5) shows workers removing loose river deposits with power shovels during foundation preparation, illustrating this application.

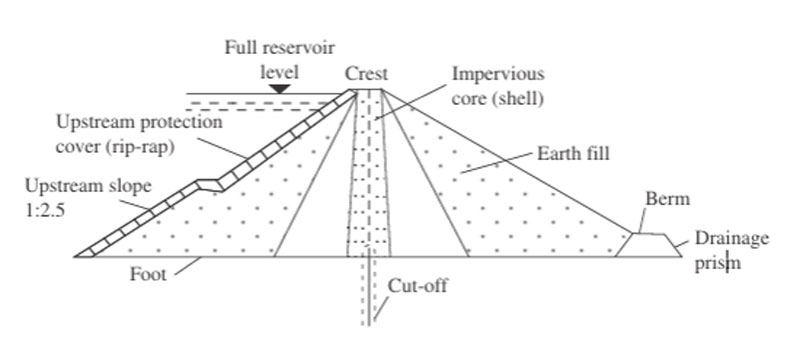

Earth Dams:

Earth dams have trapezoidal cross-sections with gentle side slopes (Fig. 6). Engineers usually build earth dams in broad valleys where constructing concrete or masonry dams would be very costly. Earth dams can rest on firm soil without rocky foundations.

Fig. 6 An earth dam with impermeable core and gentle slopes

Constructors must ensure the availability of large quantities of homogeneous earth, both pervious and semi-pervious, for the dam. Depending on materials and foundation strength, earth dam slopes commonly vary from 1:1.5 to 1:3 (vertical: horizontal).

Construction crews haul material excavated from borrow pits to the dam site with earth movers and compact it in graded layers as per design. To ensure full water tightness, builders include a clay core that acts as an impermeable membrane.

Most dams in India use earth construction because suitable earth material is abundant. Compared to other types, earth dams cost the least, covering quarrying, placement, and compression. Dams built with earth and fill material fall under the category of embankment dams.