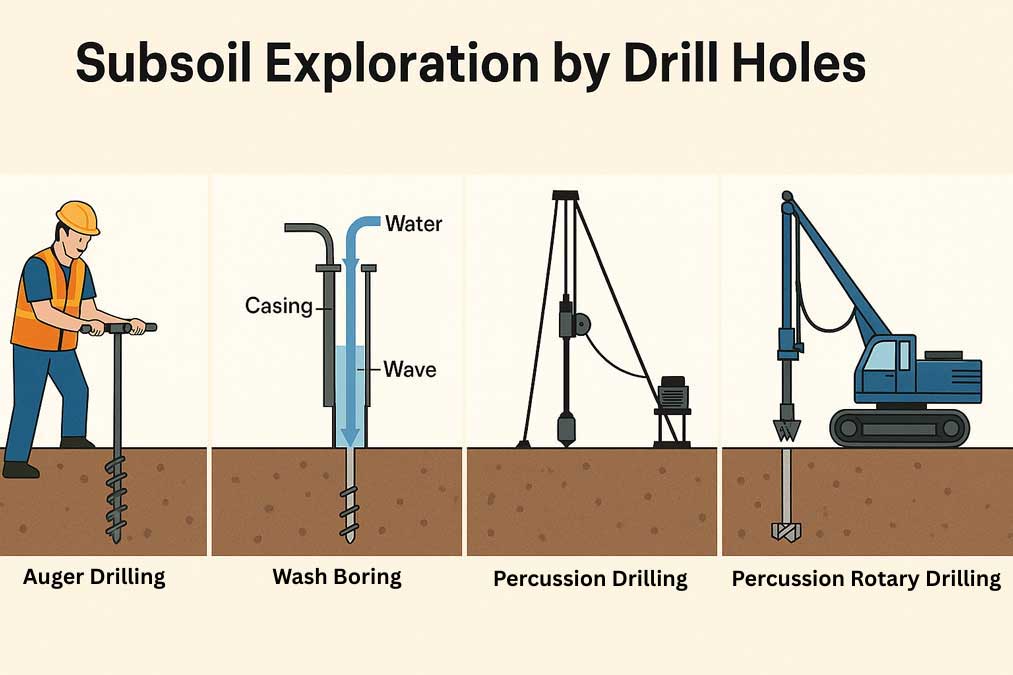

Subsoil exploration helps engineers understand what lies beneath the ground surface before starting any construction work. It identifies different soil layers and their properties. One of the common ways to explore subsoil involves drilling holes using methods such as auger drilling, wash boring, percussion drilling, and percussion rotary drilling. These methods collect soil samples and provide valuable information about ground conditions.

Subsoil Exploration by Drill Holes:

Drilling for subsoil exploration involves the following methods:

(i) Auger Drilling

(ii) Wash Boring

(iii) Percussion Drilling (free-falling)

(iv) Percussion Rotary Drilling

Auger Drilling:

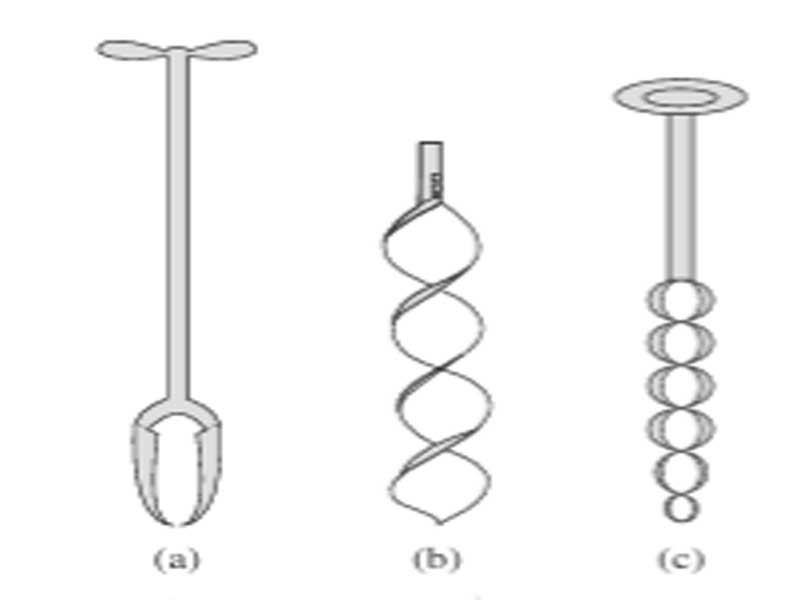

Auger drilling offers the simplest approach to subsurface exploration and soil sampling, mainly at shallow depths. Operators can use hand-operated or power-driven augers. Typically, two people operate a hand auger by turning a handle, as shown in Fig. 1(a). They press the auger into the soil while applying a turning motion to allow soil to enter the auger tip.

Fig. 1: Hand-operated augers for use in soft soil: (a) with a handle and Iwan-type sampling tip; (b) with helical spiral tip; and (c) with closed spiral tip

Hand-operated augers range from 5 cm to 20 cm in diameter and typically reach depths up to 6 m in cohesive soil above the water table. A tripod stand and a hoist help drill deeper holes. For depths greater than 6 m, operators screw together several 1.5-m-long extension rods as drilling progresses.

Augers collect disturbed samples from shallow depths. The sampling ends, which rotate to collect soil, come in various shapes, the most common being the Iwan type, helical (spiral) surface type, and closed spiral type (see Fig. 1(b)).

Power augers, often truck-mounted, drill large areas quickly. These augers have continuous flights with sharp cutting bits and can drill holes up to 35 cm in diameter, reaching depths of 50 m or more.

In addition to soil, power augers bore through sand, gravel, clay, and soft rocks like shale and chalk. Typically, auger drilling doesn’t require casing unless operating below the water table or in sandy zones.

Though the collected samples are disturbed, they help identify soil types and variations at different depths. Auger drilling is especially useful for exploring borrow areas for soil in earthen dam and highway construction. However, it doesn’t perform well in boulder-filled soils.

Wash Boring:

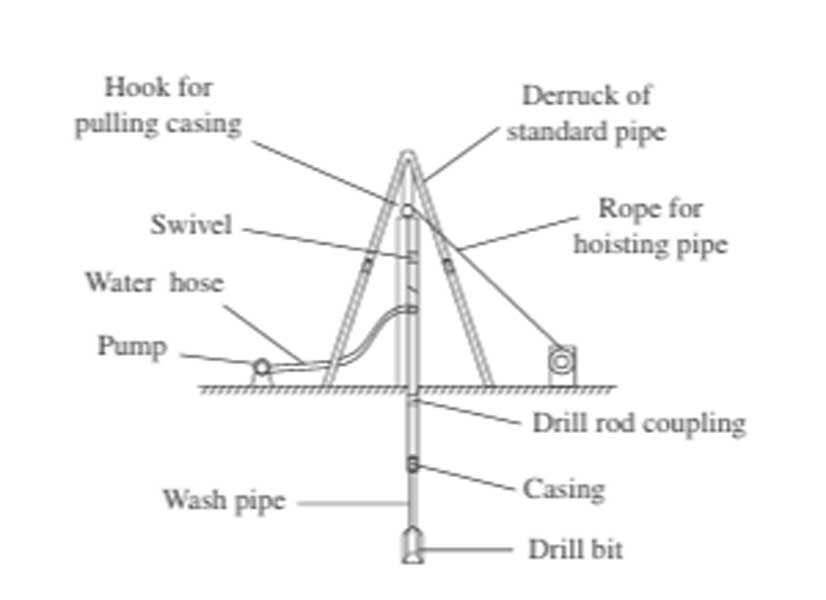

Wash boring provides an economical method for assessing general subsurface soil conditions. The equipment includes a 2 cm diameter drill rod inside a 5 cm diameter casing (Fig.2). Operators alternately raise and drop the rod into the soil.

A sharp chisel or chopping bit at the rod’s lower end breaks up the soil or soft rock. Water flows under pressure through the rod, helping bring cuttings to the surface as a soil–water slurry via the space between the rod and casing.

Fig.2: Sketch showing the different parts of the wash boring equipment

Although these “wash samples” are unsuitable for lab testing, they offer insights into soil nature and bedrock type. As drilling continues, changes in soil hardness reveal different subsurface layers.

Operators estimate bedrock depth by monitoring resistance during drilling and identifying the recovered cuttings. They determine the groundwater level by periodically measuring the water inside the borehole. To recover undisturbed samples, operators clean the hole bottom and insert appropriate sampling tools.

Percussion Drilling:

Free-fall percussion drilling uses a chisel bit suspended by a cable or attached to a drill rod. Repeated blows from the bit break soil or soft rock formations at the hole’s bottom. Although this method doesn’t provide samples suitable for lab testing, it offers a general idea of the soil formations.

Drillers commonly use this technique for overburden materials like sand and clay. The bit diameter starts at 30 cm and narrows to 7.6 cm deeper in the hole. When encountering bedrock, the falling motion crushes rather than chips the rock.

Drilling below the water table fills the hole with water. Operators use a bailer to remove the soil–water slurry or pulverized rock, keeping the hole clean for sampling.

Separate cables drive the bit and bailer. A motor-driven beam acts as a hammer to push a sampler into the soil for collection.

Percussion Rotary Drilling:

In percussion rotary drilling, both rotary and percussion movements work simultaneously. This method drills faster than falling-weight types and performs well in non-coring holes, making it a popular choice for exploration projects.

Water or air flushes the crushed rock from the hole. Equipment such as jackhammers or wagon drills handles this technique effectively. The drill uses a single-piece rod with a tungsten carbide (WC) bit that can penetrate depths up to 6 m.

Operators may also use chisel-shaped or four-part bits for even penetration. They add extension rods for deeper holes. For rock drilling, high-powered rotary machines can drill 4 cm-diameter holes down to 20 m. These tools are ideal for grouting operations in tunnels and dam foundations.