The study of rock deformation needs knowledge of the physical properties of rock about deformation. These properties are concerned either with elastic or with plastic deformation or with rupture.

Table of Content

- Elastic properties

- Plastic properties

- Rupture

- Brittle substances

- Ductile substances

- Stages of deformation

- Type of deformation

- Stress Strain Diagram

- Strain Definition

- Tensile Strength

- Stress-Strain curve

- Elongation

- Rigidity or shear modulus

- Compressibility or Bulk modulus

Elastic properties:

An elastic property is defined as the phenomenon in which the solid materials return to their original shape and size after the forces deforming them have been removed.

Plastic properties:

A material is said to behave plastic if, at stresses below a critical level, it reacts as solid, while at stresses at or above the critical level, it flows continuously without rupture to become permanently strained.

Rupture:

When there is a continued increase in the stress, one or more fractures develop, and the material eventually fails by ruptures.

Brittle substances:

Brittle substances are those that rupture before any significant plastic deformation takes place.

Example: ceramics and glass.

Ductile substances:

Ductile substances are those that undergo large plastic deformation before rupture.

Example: most metals.

Stages of deformation:

Elastic: Material is stretched, but returns to its original position.

Plastic: Material behaves in a ductile manner. One stretched, it remains deformed.

Brittle: when enough stress is applied, the material will fracture.

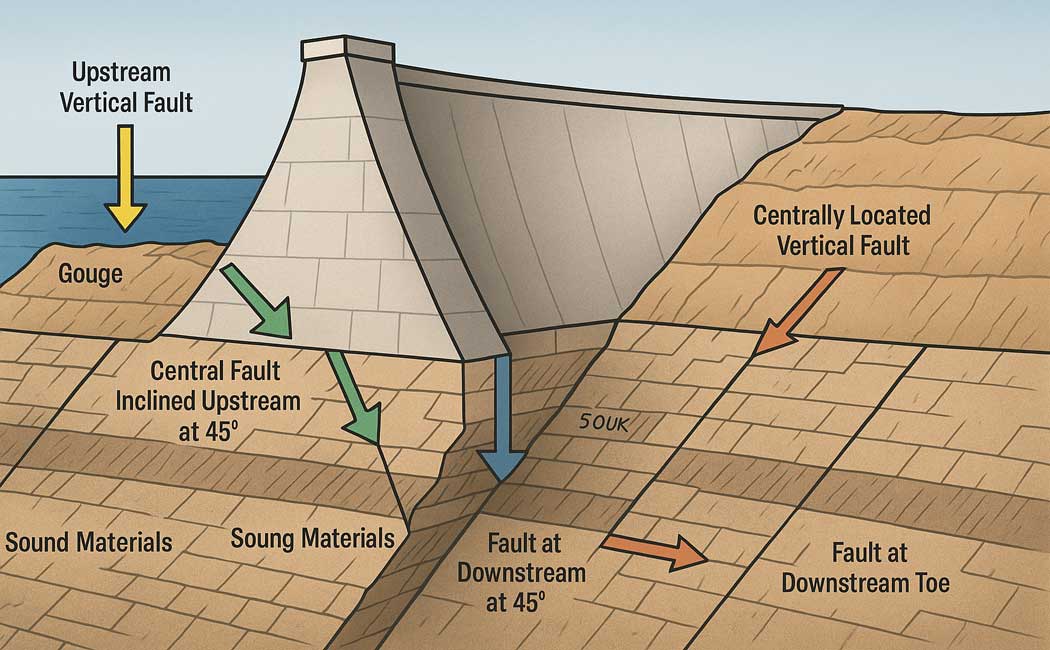

The type of deformation that occurs is dependent upon:

Rate of stress: As stress is increased, the material goes from being elastic to Plastic and finally fracturing.

Temperature: At lower temperatures, the material fractures sooner. At higher temperatures, the material behaves like a plastic longer before fracturing.

Confining pressure: The lower the pressure, the sooner the material will fracture.

Stress-strain Diagram:

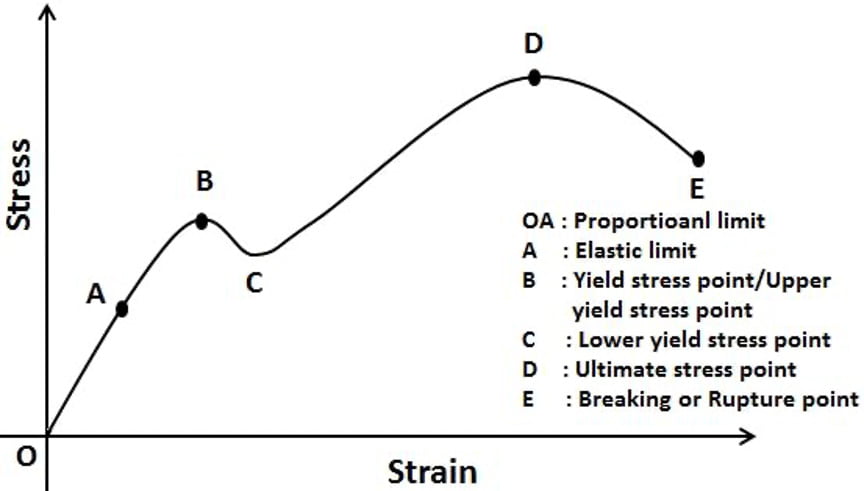

The relation existing between stress and strain is commonly expressed in graphs known as Stress-strain Diagram. The stress is plotted on the vertical axis, whereas the train is plotted on the horizontal axis.

The stress-strain curve has different regions and points. These regions and points are:

- Proportional limit:

It is the region in the Stress-strain curve obeys that Hooke’s law i.e., within Elastic limit the stress is directly proportional to the strain produced in the material. In this limit, the ratio of stress with strain gives us a Proportionally constant known as young’s modulus. The point OA in the graph is called the Proportional limit.

- Elastic limit:

It is the graph up to which the material returns to its original position when the load acting on it is completely removed. Beyond this limit, the material can’t return to its original position and a plastic deformation starts to appear in it. Point A is the Elastic limit in the graph.

- Yield point or yield stress point:

Yield point in a Stress-strain Diagram is defined as the point at which the material starts to deform plastically. After the yield point is passed there is permanent deformation develops in the material and which is not reversible. There are two yield points It is the upper yield point and the lower yield point. The stress corresponding to the yield point is called the yield stress point. Point B is the upper yield point and point C is the lower yield stress point.

- Ultimate stress point:

It is the point corresponding to the maximum stress that material can handle before failure. It is the maximum strength point of the material that can handle the maximum load. Beyond this point the failure takes place. Pont D, the graph is the ultimate stress point.

5. Fracture or Breaking point:

It is the point in the curve at which the failure of e material takes place. The fracture or breaking of material takes place at this point. The point E is the Breaking point in the graph.

Strain Definition:

Change of dimensions of matter in response to stress. It is the deformation caused by stress.

Two types of strain:

- Dilation: which is a change in Volume.

- Distortion: which is a change in shape.

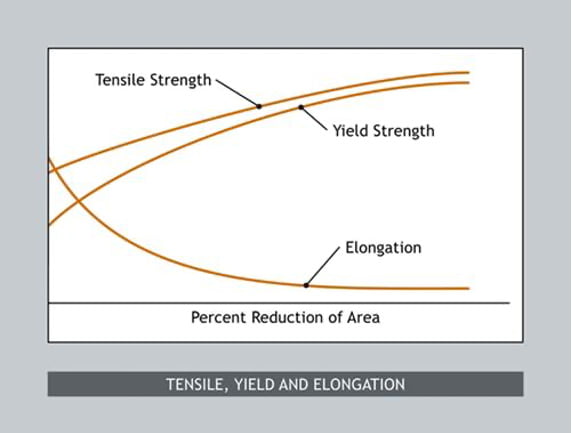

Tensile Strength:

Tensile strength is the maximum stress that a material can withstand while being stretched or pulled.

Elongation

Elongation is the measure of deformation that occurs before a material eventually breaks when subjected to a tensile load. Elongation due to expansion can also occur when a material undergoes an increase in temperature, or if both an axial force and a high temperature act simultaneously upon a material.

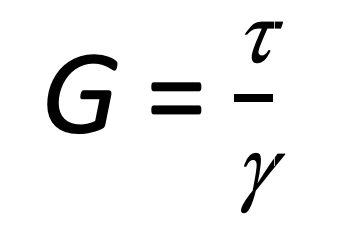

Rigidity or Shear modulus:

Within the Elastic limit, the ratio of shear stress to shear strain is called modulus of Rigidity. It is expressed by the equation,

Where G is known as the shear modulus or Rigidity.

Rigidity or shear modulus measures the resistance to change in shape.

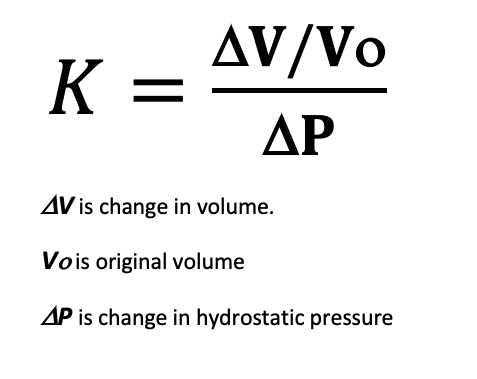

Compressibility or Bulk modulus:

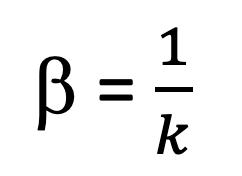

When a body is subjected to a change of hydrostatic stress, the volume change per unit pressure change is called Compressibility. It is expressed by the equation

Compressibility is the reciprocal of Bulk Modulus,